ข่าวสารและกิจกรรม

อะไหล่ ความรู้ด้านอุตสาหกรรม

What’s the difference between woven and non-woven dust filter bags?

1. Introduction to Dust Filter Bags in Industrial Filtration

- Definition and role of dust filter bags in air pollution control systems.

- Overview of industrial applications (steel, cement, pharmaceuticals, etc.), aligning with Anhui Tiankang’s expertise in dust removal systems for sectors like steelmaking, foundries, and VOC treatment.

- Importance of material selection (woven vs. non-woven) for efficiency and compliance with environmental standards.

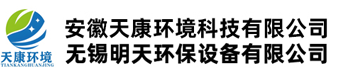

2. Woven Dust Filter Bags: Structure and Applications

- Material Composition : Yarn types (e.g., polyester, PTFE), weaving techniques (plain, twill weave), and surface treatments (e.g., calendering).

- Performance Characteristics :

- High mechanical strength and temperature resistance.

- Ideal for heavy-load industries (e.g., steel industry sintering, blast furnace tapping hoods).

- Limitations : Lower fine-particle retention compared to non-woven alternatives.

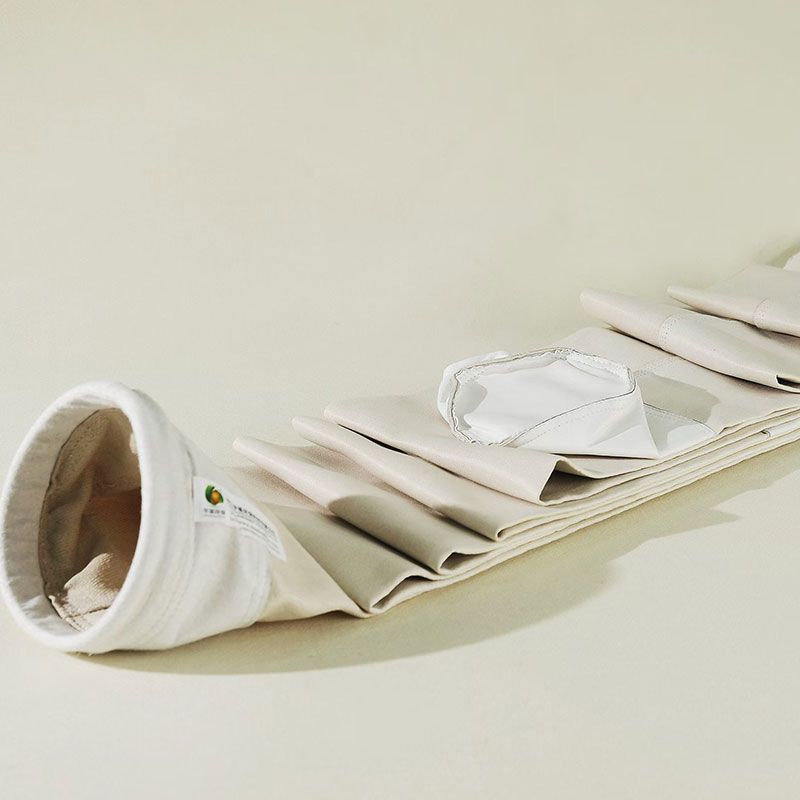

3. Non-Woven Dust Filter Bags: Technology and Advantages

- Manufacturing Processes : Needle punching, meltblown, or spunbond methods.

- Key Properties :

- Superior filtration efficiency for submicron particles (critical for pharmaceutical or cement industries ).

- Flexibility in material blends (e.g., hybrid fibers for corrosive environments like non-ferrous smelting ).

- Trade-offs : Reduced durability under high abrasive conditions.

4. Comparative Analysis: Woven vs. Non-Woven

(Use a concise table for clarity, if needed)

| Parameter | Woven Dust Filter Bags | Non-Woven Dust Filter Bags |

|---|---|---|

| Filtration Efficiency | Moderate (10–50 µm) | High (<5 µm) |

| Temperature Range | Up to 280°C (PTFE) | Typically ≤150°C (varies by material) |

| Primary Use Cases | Heavy dust loads (e.g., steel slag treatment ) | Fine particulate (e.g., VOC systems ) |

5. Selection Criteria for Industrial Scenarios

- Factors influencing choice:

- Dust particle size (linked to Anhui Tiankang’s customized hood designs for electric furnaces or converters).

- Chemical resistance (e.g., acidic flue gases in desulfurization towers ).

- Operational lifespan and maintenance (e.g., ash conveying equipment compatibility).

- Emphasis on ISO-certified testing and patented technologies for optimal performance.

6. Innovations and Future Trends

-

Advances in hybrid materials (e.g., PTFE-coated woven bags) for flue gas denitrification .

-

Role of full-chain quality systems (R&D to delivery) in enhancing durability.

-

Summary of woven/non-woven distinctions.

-

Reiteration of dust filter bags as critical components in turnkey environmental projects , supported by engineering expertise like Anhui Tiankang’s integrated solutions .

简体中文

简体中文